We can estimate the interstitial volumes of both the SPP and FPPs if we know some facts about the materials in use. Whilst a detailed treatment of this topic is outside the scope of this discussion, I would urge you to seek further information from Reference 3, which also details which changes to the gradient program might be made in order to avoid selectivity issues when large changes in V D/V M are required. Typically, we will be able to choose from 3mm or 2.1mm internal diameter columns however, we must be careful when reducing internal diameter, as making large changes to the instrument dwell volume (V D) to column volume (V M) ratio has been shown to induce changes in selectivity when using gradient methods. To ensure that this is the case, we use Equation 2 to calculate the eluent flow rate. We can also reduce the internal diameter of the HPLC column, providing that the linear velocity of the eluent is maintained.

CORE SHELL PARTICLES WIKI FULL

Let’s assume that we wish to take full advantage of the speed gains offered by SPP particles and that we will opt for the 75mm column. So, we can see that the 100 or 75mm columns are available as options when switching to 2.7μm SPP formats. We need to decide which of these columns would comply with the requirements of Chapter L

Typically, we can choose columns of 100, 75, or 50mm in length. In this case we wish to translate the USP method for Lanzoprazole and it impurities, which uses a 150 x 4.6mm column with 5μm FPP, to an SPP column which uses 2.7μm particles. That is, the column length (L) to particle size (d p) ratio must not fall outside these limits.

When changing column or particle size dimensions, for USP methods we need to comply with the requirements that To translate the various method parameters from the FPP to the SPP column, one might use the following equations For a more detailed explanation of the proposed changes to Chapter see reference. These are the people I have in mind with this piece - those who seek to improve or replace existing methods on a limited budget for new instruments.Īs well as a refresher on the simple maths required to undertake method transfer from fully porous particles (FPP) to superficially porous particles (SPP) I’m going to impose a further constraint by working within the new USP General Chapter proposition which is currently in draught form. That being said, I see so many scientists struggling with methods where an improvement in efficiency (and, resultantly, resolution) would deliver significant benefits - solving issues with their troublesome methods or identifying how shortened analytical run times may help with throughput problems.

CORE SHELL PARTICLES WIKI DRIVER

I really can’t answer this question, although I suspect that there are many legacy methods which work perfectly well on fully porous particles therefore, there is no real driver to change.

CORE SHELL PARTICLES WIKI UPDATE

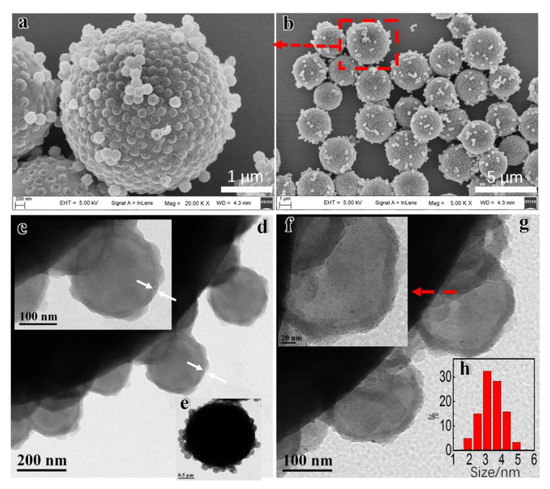

So, are we in danger of forgetting the advantages which core-shell particles can bring to methods which still use fully porous particles? Or, put differently, why do 5μm or 3μm fully porous particles still exist? And why hasn’t everyone migrated their methods to this superior technology? After all, with 2.7μm (or similar) and 5μm core-shell particles widely available why wouldn’t we all want to update our legacy methods, or seek to develop new methods using core-shell particles? In fact, I’ve lately had trouble finding an online method translator - most manufacturers have core-shell versions of their popular phases from their fully porous particle ranges. Now, it would appear the hype around core-shell particles has died down. Many of us wondered if this was a reaction to the introduction of sub 2μm HPLC particles and UHPLC instrumentation (around 2004), particularly the speed and efficiency which this approach brought to our industry. Used by HPLC column manufacturers, they promised higher performance at lower backpressures. In the late noughties we couldn’t avoid webinars, seminars, and online calculators extolling the virtues of the ‘new’ core-shell particle morphology.

0 kommentar(er)

0 kommentar(er)